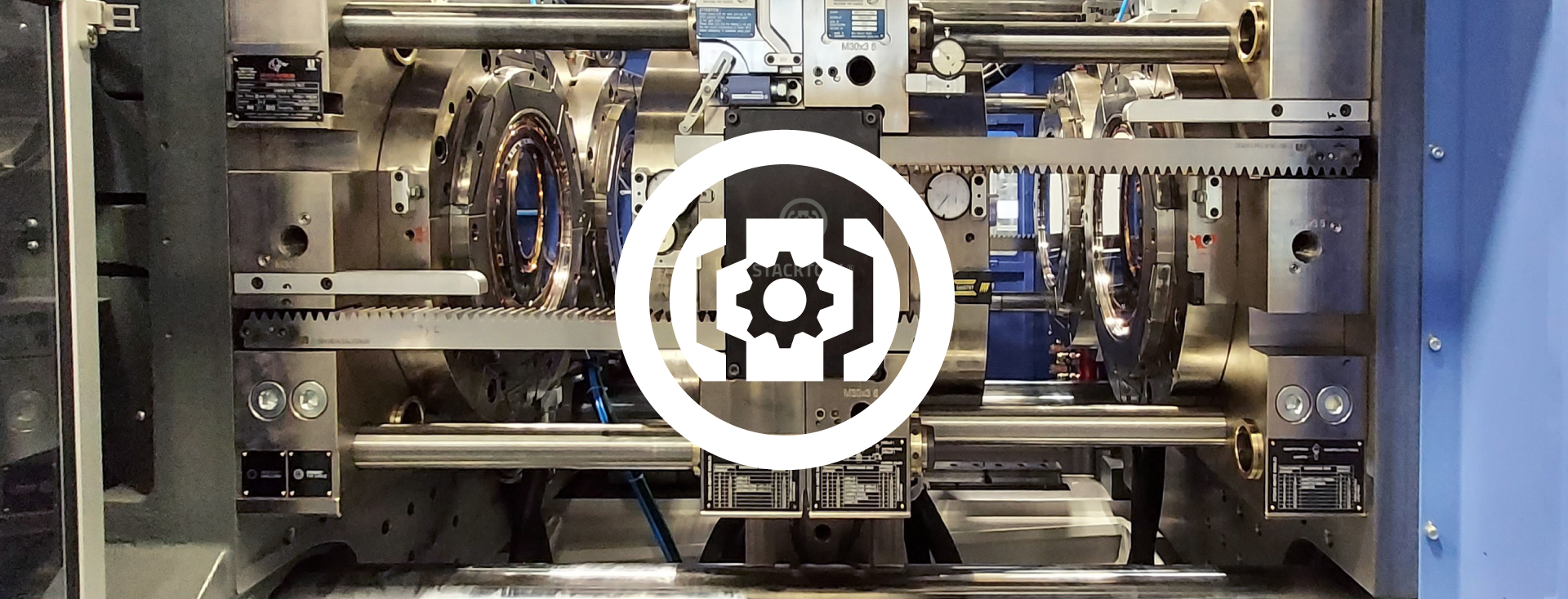

STACKTOOL®

High-performance multi-platen modular mould.

The Stacktool is an injection moulding system designed to increase production while guaranteeing repeatability and part quality.

The use of moulds with several moulding surfaces allows the production of the same injection moulding machine to be multiplied. Stacktool technology, also known as sandwich technology, therefore ensures increased production while reducing costs.

Abate Basilio Stacktool systems are designed to guarantee maximum reliability over time given the complexity of the moulds themselves.

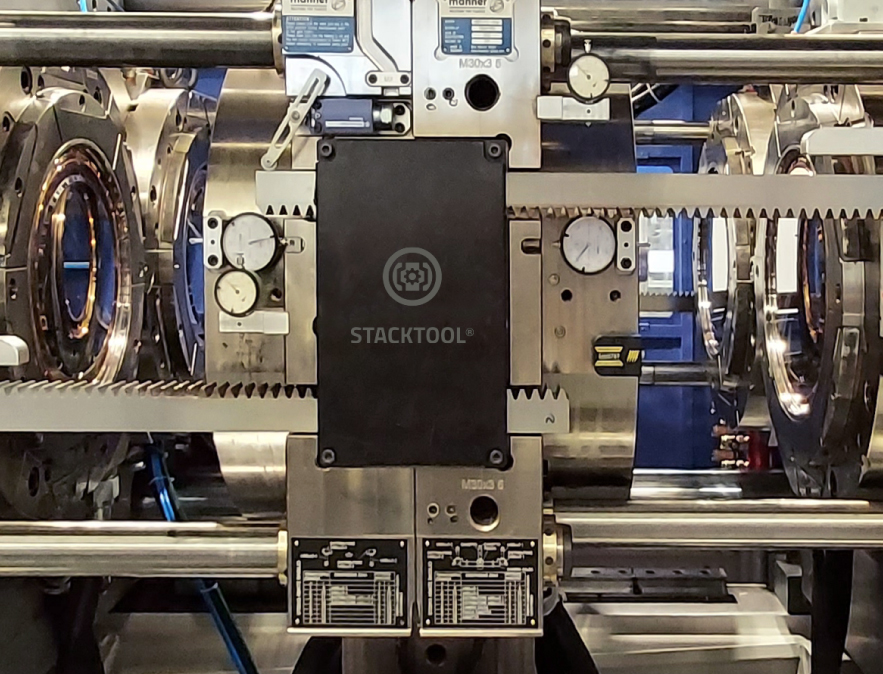

These moulds are the ideal solution to keep the tonnage required for moulding to a minimum, and to achieve the best possible cycle while producing more products, thanks to the interchangeability of the Flexomould® molding inserts.

A unique solution for increasing the productivity and economies of moulded parts, it facilitates the production of high volumes of identical or similar parts at an excellent price-quality ratio.

Our Stacktool system, specifically designed for high-performance injection moulding in packaging, features the following advantages:

-

Different opening strokes – the new concept of connection via gear and rack box or articulated systems allows the simultaneous operation of two moulds with dissimilar opening strokes.

-

Flexibility - new conception and efficiency of moulding with the possibility to execute Stacktool using our Flexomould® technology with different cavities in size and shape, while maintaining the highest quality of the moulded product.

-

Simplified Operation and Maintenance - A major study was carried out to build all the kinematics of our Stacktool using standardised components available in 48 hours on the international market.

-

Optimized for use with the patented SQUARE THE CIRCLE centering system.

-

Optimized for the use of the FLEXOMOULD modular system.

-

Optimized for the high-performance IML system.

-

Lower machine and part cost.

-

Higher production with lower investment.

Processes

Thanks to its technology, flexibility and analytical approach, Abate Basilio does not only manufacture high performance moulds for the injection of plastic materials, but also provides customized solutions for any project. Thanks to the control of the entire production chain, from planning to delivery, each mould ensures unique quality, durability and performance.

Analysis

and planning

Abate offers a service of consultancy and analysis of the customer’s needs specific for each project. A specific technical knowledge is required for each sector, from food industry to chemicals, logistics etc., in order to be able to design and manufacture the more appropriate mould for a specific product.

Construction

and testing

Our production line includes 5-axis machining centres with fully automatic tool and pallets changers which allow us to achieve maximum repeatability and quickest throughput. Our machines are equipped with a laser control of the real dimensions directly obtained during the process in order to achieve the maximum precisions.

Maintenance

and after-sale

Our technical department ensures a fast, reliable and precise after-sale service. 95% of the company production is destined to be exported to different countries located over 5 continents. Our company has always given support to customers all over the world thanks to reliable planning of the mould and availability of spare parts which are guaranteed for 20 years.