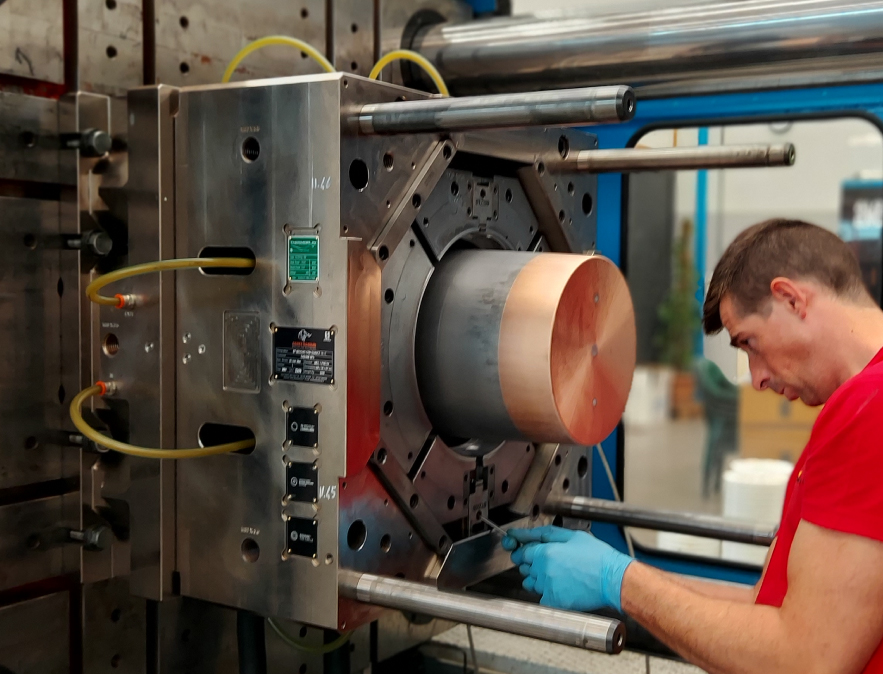

Duplex®

Double centred mould with movement wear recovery

The new Duplex® mould has several advantages that set it apart:

a) Reliability - The introduction of the new concept of adjusting and recovering mould wear offers the possibility of maintenance directly on the machine, avoiding costly production stops. This gives a significant advantage in terms of operational efficiency;

b) Ease of use - The mould has been designed with the aim of offering a simple and safe user experience. This is a distinguishing feature from competitor cheek moulds, which often present operational complexities.

c) Reduced maintenance - An additional purpose of the present invention is to provide a moulding device capable of ensuring high quality and dimensional accuracy of the moulded products over time, and consequently to provide an injection moulding device that minimises maintenance.

d) Increased service life - An additional purpose of the present invention is to propose an injection moulding device having a significantly increased service life.

e) Decreased environmental impact - The increased centring capacity of this device will make it possible to decrease the thickness of the moulded parts with a great saving in raw materials, thus reducing the environmental impact.

-

Is designed to optimise the IML system.

-

Mould is designed to optimise the Quadrowings closure system.

-

Takes advantage of the patented INNERCORE EXTRA COOLING SYSTEM.

Processes

Thanks to its technology, flexibility and analytical approach, Abate Basilio does not only manufacture high performance moulds for the injection of plastic materials, but also provides customized solutions for any project. Thanks to the control of the entire production chain, from planning to delivery, each mould ensures unique quality, durability and performance.

Analysis

and planning

Abate offers a service of consultancy and analysis of the customer’s needs specific for each project. A specific technical knowledge is required for each sector, from food industry to chemicals, logistics etc., in order to be able to design and manufacture the more appropriate mould for a specific product.

Construction

and testing

Our production line includes 5-axis machining centres with fully automatic tool and pallets changers which allow us to achieve maximum repeatability and quickest throughput. Our machines are equipped with a laser control of the real dimensions directly obtained during the process in order to achieve the maximum precisions.

Maintenance

and after-sale

Our technical department ensures a fast, reliable and precise after-sale service. 95% of the company production is destined to be exported to different countries located over 5 continents. Our company has always given support to customers all over the world thanks to reliable planning of the mould and availability of spare parts which are guaranteed for 20 years.